About Sanray Laboratories

We as a company values integrity, personal excellence, and continual improvement. We commit to the customers and take pride in serving them and striving for the highest quality. The senior management and the staff are independent, engaged, committed, and effective. Our Management establishes, maintain, and monitor standards and policies for ethics, business practices, and compliance across the company.

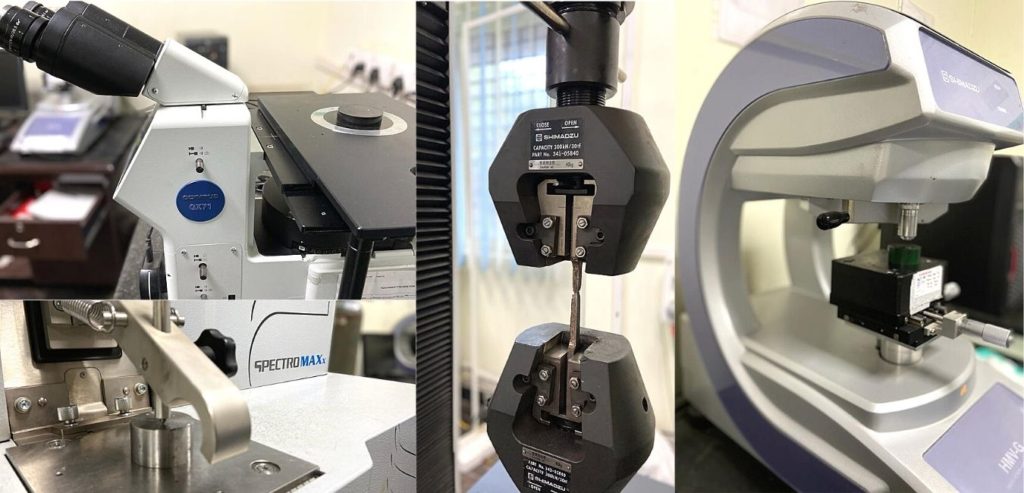

The services SANRAY provides Mechanical Testing, Metallographic and Microscopic Studies (SEM, Optical Microscope, EDS, EDAX, XRD,), Chemical Analysis, Microbiology Testing, Food safety, Pharmaceutical, Nano Materials Testing, Environmental testing as per JSS, Civil Testing, Positive Material Identification (PMI including onsite carbon detection), Non-Destructive Testing, Ferrite Measurement, Portable Hardness, Thermography), Welder Qualification (as per ASTM, ASME and API), In-situ Metallography (with SEM and EDAX), Corrosion Testing (Salt Spray, Inter-granular Corrosion), Failure Analysis, Finite Element Analysis, Factory Audits, Third Party Inspection, Metallurgical Product Evaluation, Post Weld Heat Treatment, Engineering Research, Reverse Engineering, and Consultancy.

We provide reliable, affordable, and accurate testing services as per National and International standard methods as defined by ASTM, NACE, DIN, AWS, API, ASME, BIS, IS, ISO, JSS and others, non-standard methods, laboratory-developed methods, and customer supplied methods using well-equipped facilities and state-of-the-art instruments.

Customer Service Representatives, at SANRAY, provide clients with up-to-the-minute information on the status of a sample through laboratory information management system (LIMS) software.

Laboratory management system (accredited to ISO 17025 for all the departments) assures that all sample specimens are properly handled, machined, tested, examined, and inspected in accordance with test requirements. The mission of the Quality Assurance Department is to maintain the ISO 17025 established standards of quality, and for the development and application of the systems and procedures necessary to meet or exceed the quality requirements of all customers. The Quality Assurance Department conducts frequent and vigorous internal audits to ensure the highest possible level of quality offering